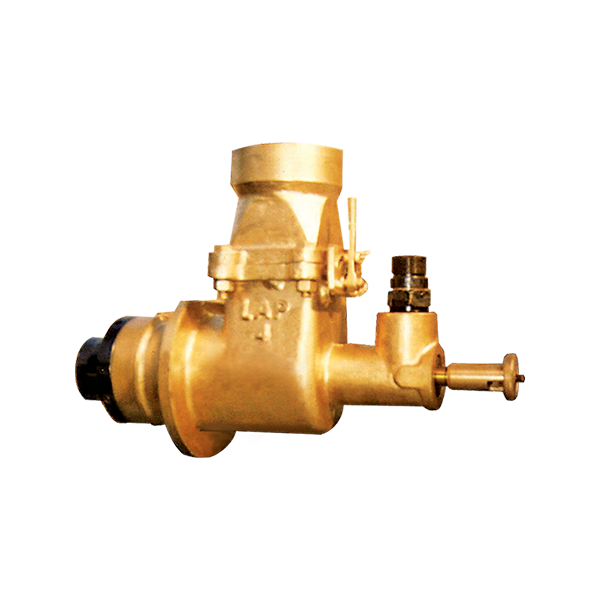

Low Air Pressure Industrial Oil Burner

Characteristics

Low Air Pressure Burners are suitable for most classes of liquid fuels. They operate with a stream of high velocity air, at a specified pressure, for fuel atomization. The burners have good 'turn down' range and hence rate of fuel consumption can be adjusted through a great extent without affecting the quality of combustion. The flame can be set for short and thick flame or long and narrow flame. Due to the ease of operation of the burner, a semiskilled operator is enough to handle the same.

Constuctional Features

The burner body is made of high grade alloy cast iron and is sturdy. The atomizer is stationary and could be easily dismantled for cleaning up the burner. Strict quality control is made at our factory, before the burners are of streamlined construction to reduce frictional losses.

Operation

The fuel is to be supplied to the burner either by gravity or by a constant pressure pumping system, at a pressure of 0.55-0.85 kg./cm² (8-12 PSI). Air supply is to be provided by a blower at a pressure of 400-750 mm WG. If the fuel used is a thick oil, eg. Furnace oil, it has to be preheated to bring down its viscosity, to less than 100 Sacs Redwood No. 1, at the burner. When the ambient temperature is below 150C, an outflow heater has to be fitted in the oil service tank for uninterrupted fuel supply to the burner. It is important to filter the furnace oil through reliable coarse and fine oil filters, to ensure clean oil supply to the burner.

The burner output is adjusted by rotating the wheel attached to the oil regulating valve. The length of flame is adjusted by operating the swilled flap valve for the airflow.

Applications

Due to the superior design and performance, the burners are extensively used for Various types of oil Fired Furnaces for Glass, Bricks & Ceramics, Bakery ovens, Kilns and Galvanizing equipment, Varnish Pots, Tea Driers, Chemicals Plants, Rolling Mills, Foundry Ovens, Boilers etc.

Selection chart for L.A.P. Burners

| Size of Burner | Oil Consumption in Lit/hrs | Oil Connection | Air Connection | H.P. of Blowers | Blower Capacity M3/Min | Total Pressure in MM WG. | Oil Preheater |

| L.A.P- 00 | 2 - 6.5 | ¾" BSP | 1" BSP | 1 HP | 5 | 450 | 1 kw |

| L.A.P- 0 | 4 - 11 | ¾" BSP | 1½" BSP | 2 HP | 12 | 450 | 2 kw |

| L.A.P- 1 | 6 - 28 | ¾"BSP | 2" BSP | 3 HP | 15 | 500 | 3 kw |

| L.A.P- 2 | 21 - 57 | 1¼" BSP | 3" BSP | 5 HP | 17 | 600 | 4.5 kw |

| L.A.P- 4 | 32 - 110 | 1¼" BSP | 4" BSP | 7.5 HP | 26 | 600 | 6 kw |