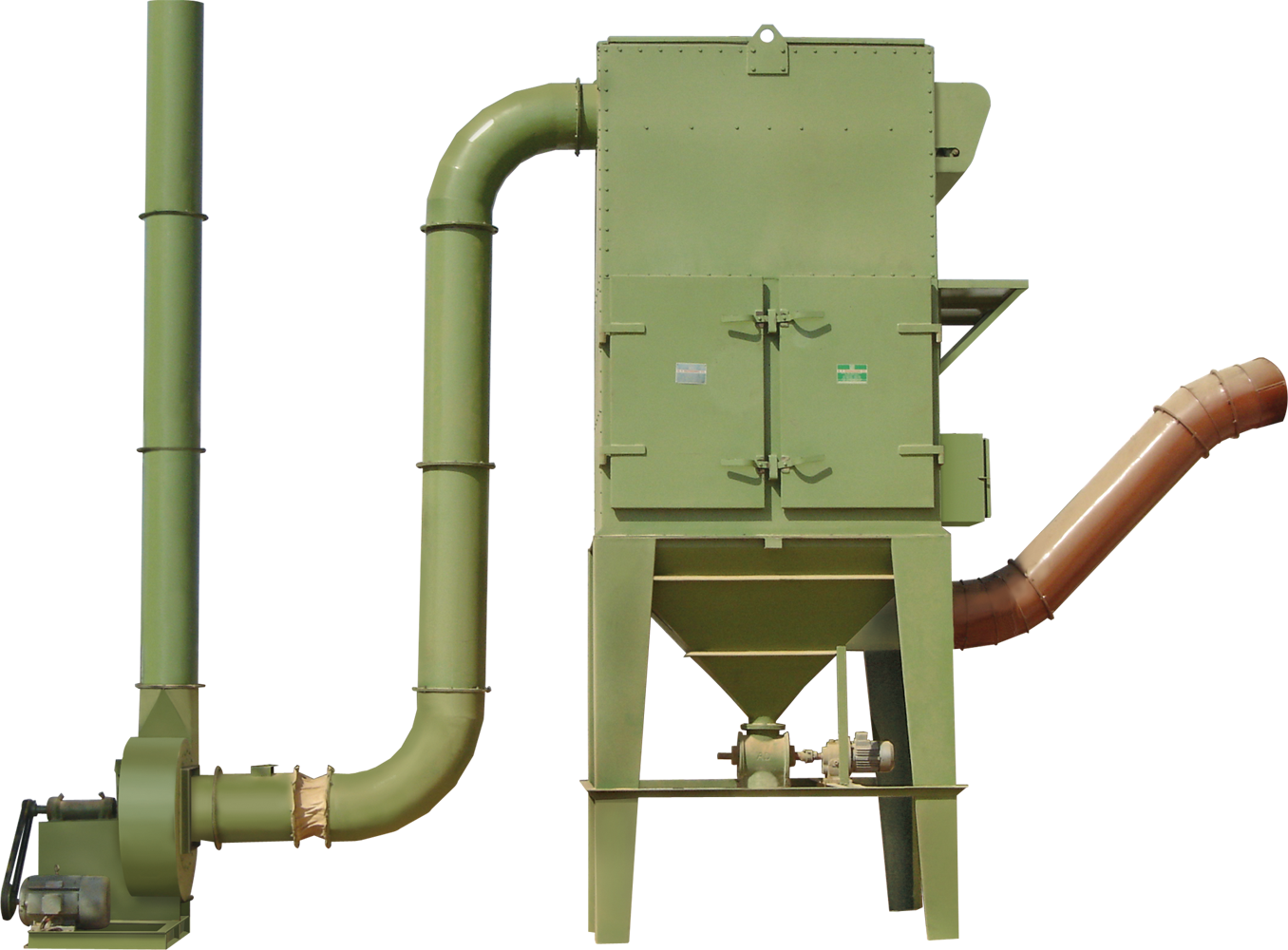

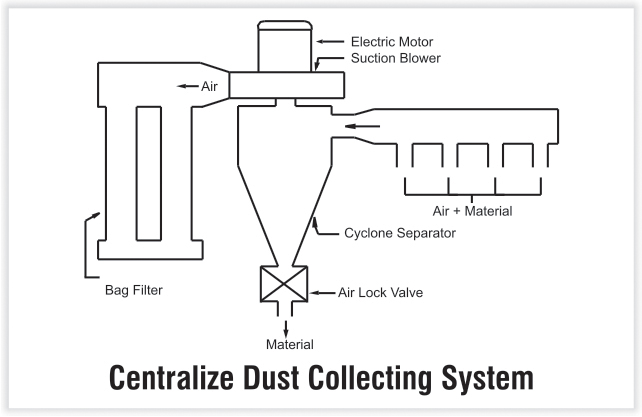

Centralize Dust Collector

DC 55 Centralize Dust Collector

DC 56

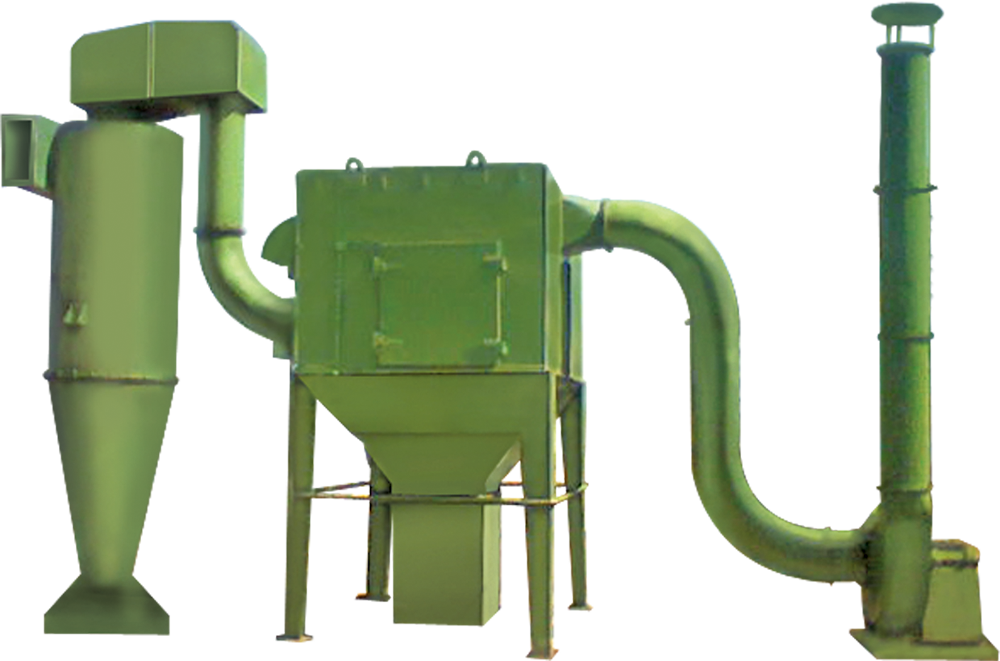

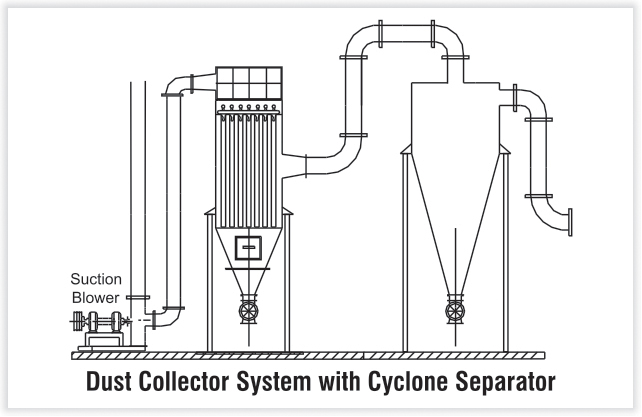

Centralize Dust collector

with Cyclone Separator

.jpg)

DC 57 Centralize Dust Collector (For Boiler Application)

"AIR KING" Make Fabric Dust Collectors-Bag Filter AKPC/AKMC

- Balanced design to achieve high efficiency.

- Auto pulse jet cleaning/mechanical shaker cleaning systems available.

- Low/Medium ratio fabric filter.

- Low maintenance/Low operation cost.

The AKPC / AKMC Bag filter utilizes our many years of experience in the field of bag filters. The AKPC/AKMC filter can effectively be used for Saw Mills, Cement Mills, Process Industries, Chemical industries, Pharmaceutical industries and Food Processing Industries with proven Performance.

It has an extensive Air / Gas flow capacity ranging from 500 to 90,000 m³/ hr. It can design to work at high temp. up to 300°C.

The bag filter type AKPC / AKMC is a high efficient collector and is intended for

manual / continuous automatic service at low / high air to cloth ratio. It consists

essentially of an air tight housing containing filter bags, bag cages, hopper and

any dust discharge equipment, compressed air cleaning equipment and timer.

The dust laden Air / Gas entry into the filter is made though a hopper. The inlet

at the hopper is provided with baffles and perforated plate which has a dual

purpose of collecting coarse particles and gas distribution. The inlet dust

concentration for these filters should be limited to 40 gm / m³.

Accessories

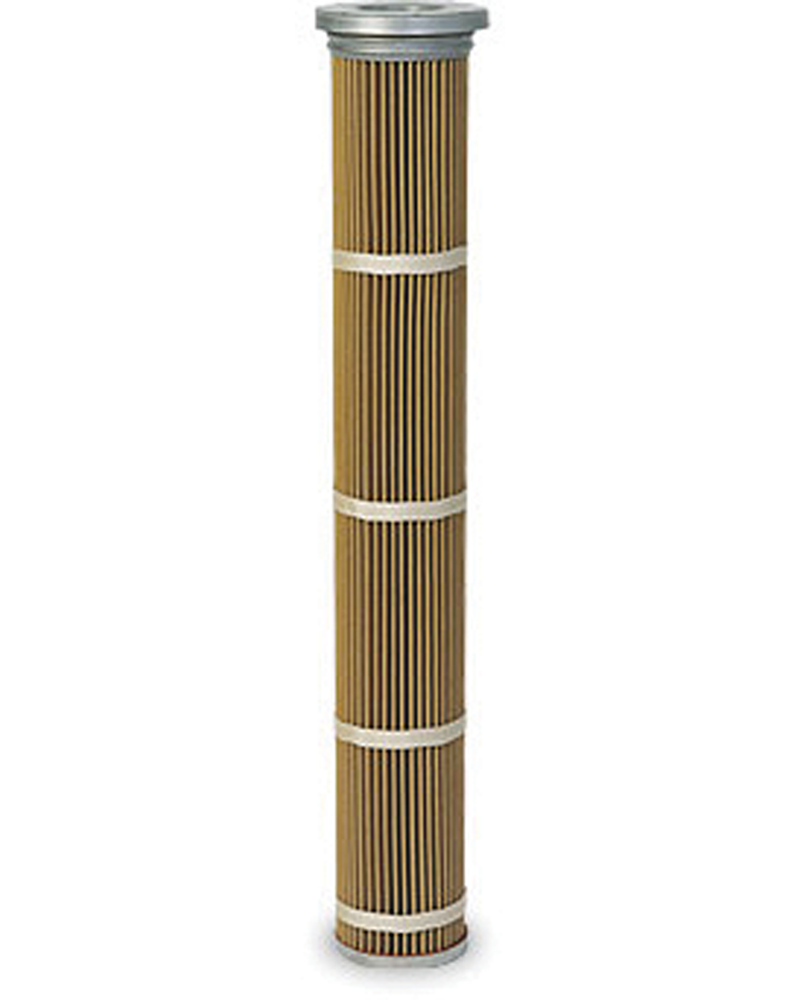

Cartridge Filter

Wire Cage

Filter Bag

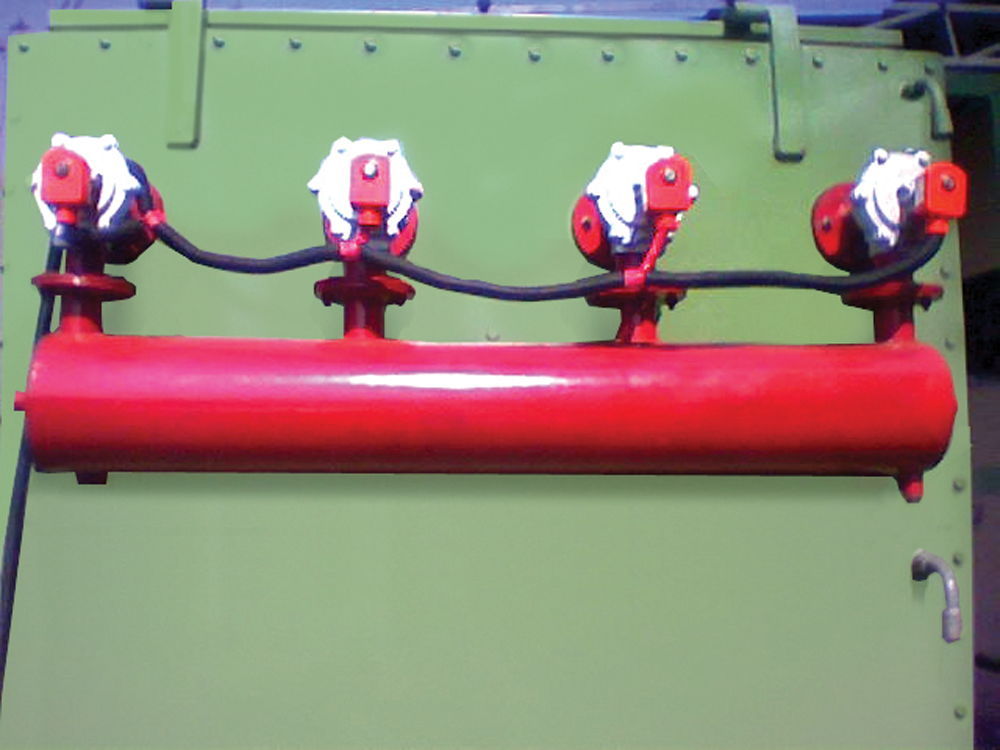

Pulse Cleaning

Pleated Bags

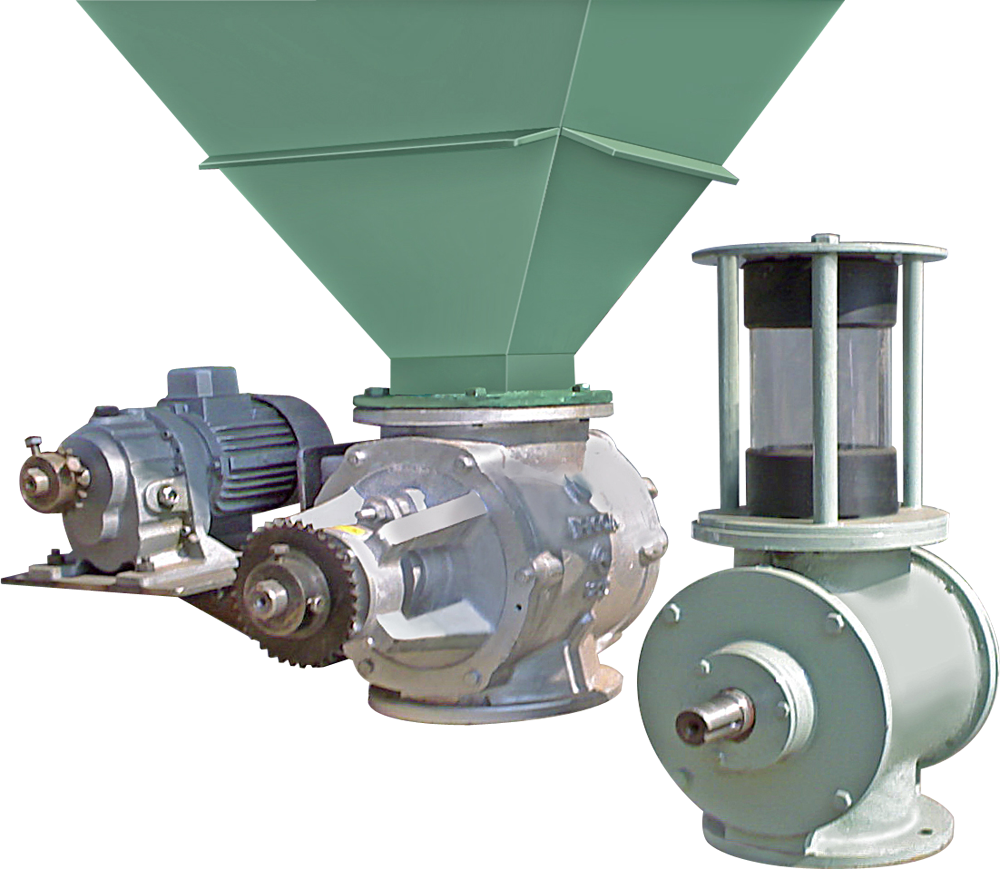

Air Lock Valve

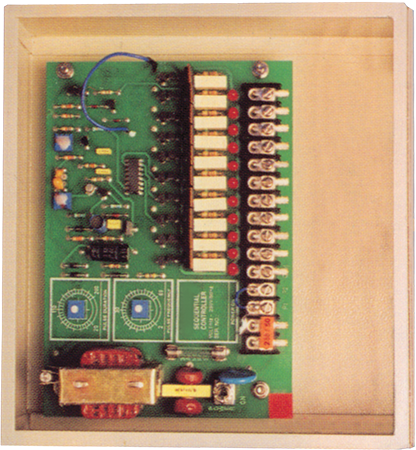

Sequential Timer

Solenoid Valve

Salient Features :

- Heavy construction with stiffeners.

- Hopper entry with baffles and plates.

- Filtration cloth area 8.0 m² to 1500m².

- Inlet pressure : up to 800 mm WG.

- Wide choice of bag 4”/ 6” dia & up to 5 met. length with suitable Fabric / Media.

- Easy installation & maintenance of bags.

- Well designed-Most efficient venture and cage assembly.

- 12 / 25 / 40 / 50 NB angle type solenoid diaphragm air pulse valve max. I4 Bags / each valve.

- Automatic 2 compressed Air - Pulse cleaning at 4-6 kg / cm pressure, and Air should be as free from Water and Oil as possible (max. 22 gm of water and 0.02 gm of oil per m³ of free air) with sequential timer

- The cleaning is done on sequential basis based on bag row selection &continues based on either preset on & pause time or fabric filter differential pressure

- The dust collected at the hopper (may be pyramidal or trough) is carried away by means of a rotary feeder or a screw conveyor.

| Fiber (Generic Name) |

Continuous Operating Temp°C |

Max Short Duration Temp°C |

Strong Acids |

Weak Acids |

Strong Alkalis |

Wealk Alkalis |

Solvents | Oxidizing Agents |

Hydro- lysis Resis- tance |

| Polyester | 150 | 170 | Good | Good | Poor | Fair | Good | Very Good | Poor |

| Polypropelene | 90 | 100 | Very Good | Very Good | Very Good | Very Good | Very Good | Good | Very Good |

| Polyamide | 110 | 120 | Poor | Good | Good | Good | Good | Good | Fair |

| Polyaramid | 200 | 220 | Fair | Good | Good | Good | Good | Good | Fair |

| Acrylic (Homopolymer) |

130 | 140 | Good | Good | Good | Good | Good | Good | Good |

| Acrylic (Co-Polymer) |

120 | 130 | Fair | Fair | Fair | Fair | Fair | Fair | Fair |

| Polyphenylene Sulphide |

190 | 210 | Good | Good | Fair | Good | Good | Poor | Very Good |

| PTFE | 250 | 260 | Very Good | Very Good | Very Good | Very Good | Very Good | Very Good | Very Good |

| Co-Polymide | 240 | 260 | Good | Good | Poor | Good | Fair | Fair | Good |

The information is based on fiber manufacturers values and as such intended for guidance only. For more in depth details on materials suitability please contact our sales department.