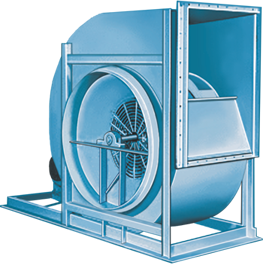

Centrifugal Suction / Flow Blower manufacturer in India

There has been a long felt need for high efficiency, trouble-free high speed Blowers and this has been achieve successfully with the introduction of our "AIR KING" Centrifugal Suction/Flow Blowers which have embodiment of special features like:-

- HIGH EFFICIENCY

- MORE AIR WITH LESS H.P.

- MOTOR DRIVE OR BELT DRIVE

- ANY DISCHARGE POSITION

- SMOOTH IN RUNNING

- NON OVERLOADING TYPE

- EASY IN OPERATION

Single Stage Blower

Volume : 100 C.F.M. to 60000 C.F.M.

Pressure : 25 m.m. to 1300 m.m. W.C.

Drive Type : Direct / Belt / Couple

Two Stage Blower

Volume : Max. 1800 C.F.M.

Pressure :Max. 2000 m.m. W.C.

Drive Type : Direct / Belt / Couple

These advantages make "AIR KING" Centrifugal Blowers leader in the field.

Robust, Welded, M.S. Sheets and Plates reinforced with angle iron frame, Suction side is provided with wire gauge to meet all safety standards. The Blowers can be supplied with any type of outlet direction of rotation and discharge to specific requirement of the Customers.

Each type has been provided in many installations throughout the country.

Types of Blowers

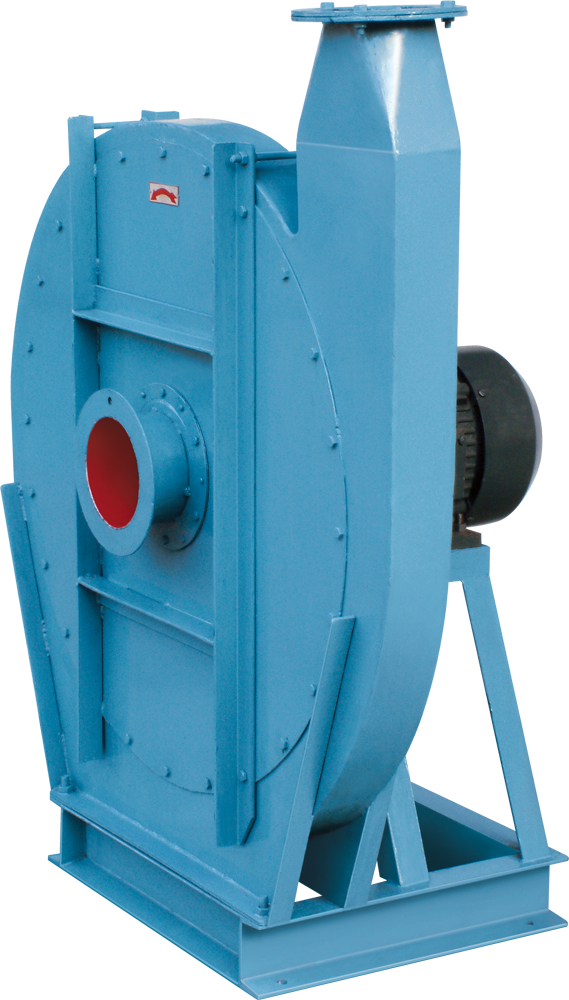

Single Stage Blower

All Belt driven Blowers are provided with EN-8 Steel shaft extension running in Ball bearing of ample size, housings in rigid housings. The shaft is provided with V type or Flat Pulley of suitable size. The whole Blower with the V. Belt drive is mounted on M.S. Fabricated Base Plate. It is also available with stuffing box, to prevent the leakage of gas for chemical factories, or with dissipating disc for air cooling of bearings.

Motor Drive

All direct motor drive Blowers are supplied with suitable size of Totally Enclosed Fan Cooled motors and suitable for phase 230/440 Volts. 50 Cycles A.C. Supply. Fans can be supplied with single / 3 phase Motors and also with flame proof motors.

Couple Drive

All motor coupled Blowers are supplied with suitable couple set as per blower capacity. And with suitable size of Totally Enclosed Fan Cooled motors and suitable for 3 ph. 400/440 Volts. 50 Cycles A.C. Supply. Fans can be supplied with single phase Motors and also flame proof motors.

Centrifugal Blower Range

Single Stage Blowers

- Range : 0.25 H.P. to 100 H.P.

- Volume : 100 C.F.M. to 60000 C.F.M.

- Pressure : 25 m.m. st.W.C. to 1300 m.m st.W.C.

Two Stage Blowers

- Range : up to 1800 C.F.M. Max.

- Volume : up to 2000 m.m. st. W.C.

- Pressure : 25 m.m. st.W.C. to 1300 m.m st.W.C.

Also Available:

- High pressure blowers for oil fire furnaces & cupola furnaces.

- Suction blowers for dust, vapor, powder, gases, hot air and light materials handling.

- S.S. 304/ S.S. 316 quality sheet fabricated blowers for chemical plants.

- P.P./ F.R.P.lining / rubber lining.

- For other applications as per your requirements.

Characteristic Curve for Centrifugal Blowers:

Selection Chart

| Press.in inches W.G. | 1 | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 28 | 32 | 36 | 48 | 50 |

| Motor H.P. | Approximate capacity in Cu. Feet / Minute. at N.T.P. | ||||||||||||||||

| 0.25 | 750 | 400 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 0.5 | 1500 | 800 | 500 | 400 | 320 | 260 | 200 | 160 | 130 | - | - | - | - | - | - | - | - |

| 1.0 | 3000 | 1600 | 1050 | 800 | 640 | 530 | 400 | 320 | 260 | 200 | - | - | - | - | - | - | - |

| 2.0 | 6000 | 3200 | 2130 | 1600 | 1280 | 1060 | 800 | 640 | 530 | 400 | 320 | 270 | - | - | - | - | - |

| 3.0 | 8000 | 4800 | 3200 | 2400 | 1920 | 1600 | 1443 | 1155 | 950 | 720 | 570 | 400 | 340 | - | - | - | - |

| 5.0 | 11500 | 7350 | 5150 | 4000 | 3200 | 2650 | 2400 | 1925 | 1600 | 1203 | 960 | 800 | 570 | 500 | - | - | - |

| 7.5 | 14500 | 10250 | 7500 | 6000 | 4800 | 4100 | 3000 | 2880 | 2400 | 1800 | 1440 | 1200 | 1030 | 750 | 650 | - | - |

| 10.0 | 20000 | 13400 | 9750 | 8000 | 6400 | 5330 | 4000 | 3850 | 3200 | 2400 | 1925 | 1600 | 1375 | 1000 | 880 | - | - |

| 12.5 | 27500 | 17000 | 12500 | 10000 | 8000 | 6660 | 5000 | 4800 | 4000 | 3000 | 2600 | 2000 | 1720 | 1500 | 1100 | 900 | - |

| 15.0 | 33000 | 20000 | 15250 | 12000 | 9600 | 8000 | 6000 | 5775 | 4800 | 3600 | 2880 | 2450 | 2000 | 1800 | 1600 | 1100 | 960 |

| 20.0 | 45000 | 25000 | 18500 | 16000 | 12800 | 10600 | 7800 | 7700 | 6400 | 4800 | 3850 | 3200 | 2750 | 2400 | 2130 | 1450 | 1280 |

| 25.0 | 55000 | 40000 | 28000 | 18000 | 16000 | 13330 | 10800 | 9600 | 8000 | 6000 | 4800 | 4000 | 3430 | 3000 | 2200 | 1850 | 1600 |

| 30.0 | - | 48000 | 34000 | 24000 | 19200 | 16000 | 12000 | 11500 | 8800 | 7200 | 5600 | 4800 | 4100 | 3600 | 3200 | 2200 | 1900 |

| 40.0 | - | 65000 | 48000 | 34500 | 24000 | 21300 | 16000 | 15400 | 10500 | 9600 | 7700 | 6410 | 5500 | 4800 | 4200 | 2900 | 2550 |

| 50.0 | - | - | 53000 | 40000 | 32000 | 26000 | 20000 | 17500 | 13300 | 12000 | 9600 | 8020 | 6870 | 6000 | 5350 | 3650 | 3200 |

| 60.0 | - | - | - | 48000 | 38000 | 32000 | 24000 | 19200 | 16000 | 14400 | 11550 | 9600 | 8250 | 7200 | 6400 | 4360 | 3800 |

| 75.0 | - | - | - | - | 48000 | 40000 | 30000 | 24000 | 20000 | 18000 | 14450 | 12000 | 10300 | 9000 | 8000 | 5400 | 4800 |

| 100 | - | - | - | - | - | 53000 | 40000 | 32000 | 26600 | 24000 | 19000 | 16000 | 13750 | 12000 | 10700 | 7300 | 6400 |

Optional Features :

- Access Door : It is for quick access to casing interior and impeller for inspection and cleaning. The door is designed to match the scroll curvature and made leak proof with a gasket.

- Split Housing : Easier access to impeller for maintenance & repair.

- Drain Plug : A coupling or flanged type to the lowest point on the casing for draining of condensate or other liquid.

- Dissipating Disc : Cast Aluminum make disc for air cooling of the bearing & shaft.

- Gland Packing : For Chemical / Dust / Powder / Gas conveying blowers at the shaft side on the casing we can provide Gland packing to prevent the leakage.

Applications :

- Crucible Furnaces, Oil Fire Furnaces, Cupola Furnaces, Ceramic Industries, Chemical Plants, Cattle Feeds Plants, Rolling Mills, Flour Mills, Cement Factories, Fertilizer industries, Boilers, Plastic Machinery Plants.

- Textile Mills & Process Industries, Hot Mix Plants & Suction Blowers for Dust, Vapor, Powder, Gases, Hot Air, And Light Materials Handling And for many other industries.

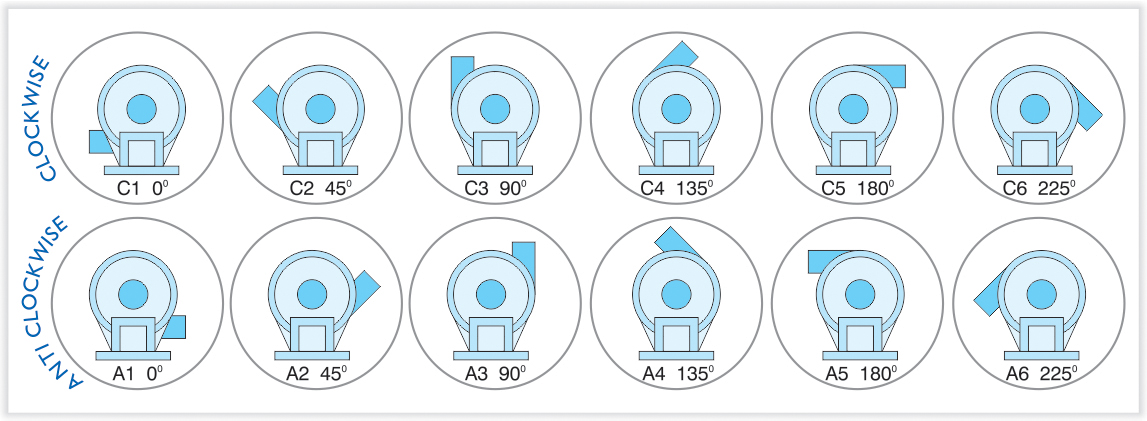

Please Specify Clockwise / Anticlock wise Direction of the blower from below mentioned Table :

For Enquiries related to Centrifugal Suction/Flow Blowers Pl. send below inputs :

- Volume in C.F.M. or M3/Hr.

- Static Pressure in Inches or M.M. of Water Gauge.

- Operating Temperature.

- Direction of rotation and discharge.

- Fan arrangement. (Direct/Belt/Couple drive)

- Any other accessories desired.

Casing and Impeller for Centrifugal Blowers

Casing

- Casings are of mild Steel / S.S. 304/ S.S.316 / F.R.P. / M.S.R.L. of ample thickness and reinforcements, sufficient to preclude drumming.

- Casing shape is designed so as to obtain efficient pressure conversion.

- Drain Plug, inspection door and stuffing box can be provided.

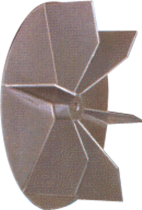

Impeller

Open Type

Backward Curve

Aerofoil Type

Forward Curve

Multiblade Type

Paddle Type

- Impellers are fabricated from M.S. Sheets and plates.

- All Vanes are hand riveted and welded for long life.

- Clearance between impeller and the casing is so controlled, as to minimize air slippage, resulting in high volumetric efficiency and are accurately statically and dynamically balanced for smooth operation.

- Design of the impeller may be changed as per application.